Ideal Info About How To Control Corrosion

Copyright © 2008 john wiley & sons, inc.

How to control corrosion. Control of corrosion since both the cathodic and anodic steps must take place for corrosion to occur, prevention of either one will stop corrosion. The most obvious strategy is to stop both processes by coating the object with a. Microbiologically influenced corrosion (mic) occurs when either aerobic or anaerobic bacteria leads.

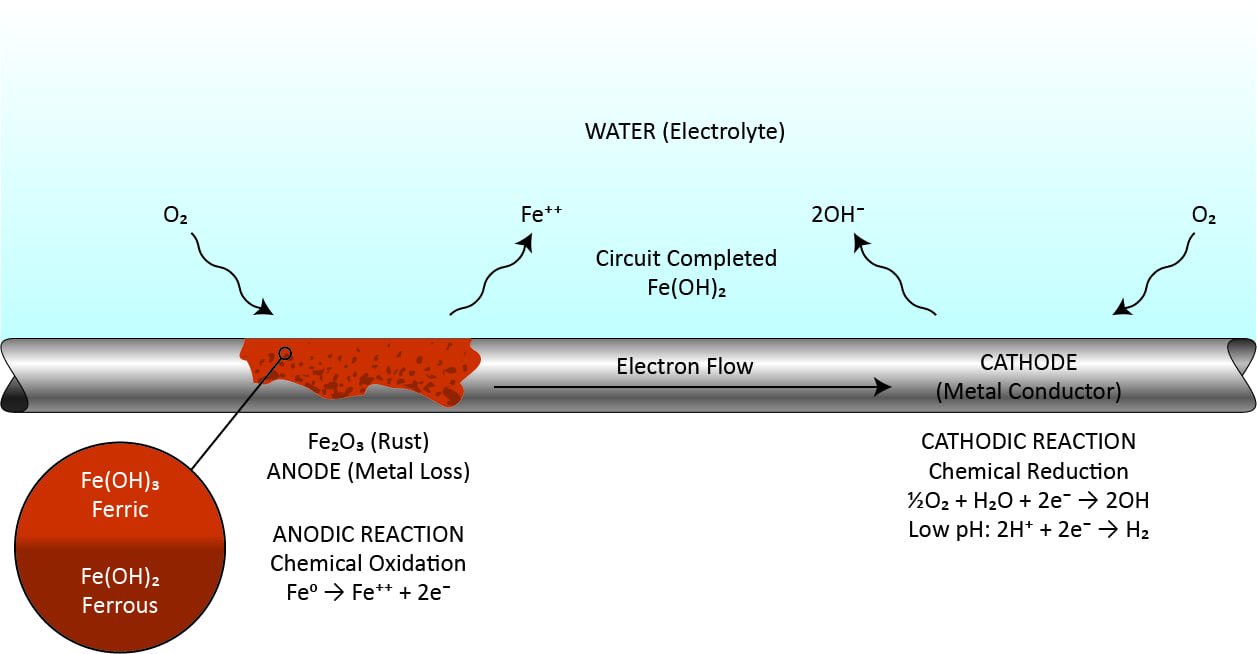

[1] in the most common use of the word, this means electrochemical oxidation of metal in reaction with an oxidant such as oxygen, hydrogen or hydroxide. There are different ways to prevent corrosion. The deterioration of metals through oxidation is a galvanic process called corrosion.

Each has its own benefits and disadvantages. Corrosion management is a vital way to help avoid catastrophic environmental and safety events as well as reduce the cost of corrosion control. Steps to establish a corrosion control system.

In most cases more than one approach is applied to any one situation. There are many approaches to the management of corrosion. A suitable corrosion protection technique can prevent corrosion of these metallic pipelines, particularly in hostile environments, and corrosive soils.

They rely on the environment and on the metal itself. Accept it will occur and periodically replace affected elements. To reduce the intensity of corrosion, they are commonly added in small amounts to acids, cooling waters, steam, and many other environments, either continuously or intermittently.

A corrosion inhibitor reduces the corrosion rate of a metal exposed to that environment by slowing down the chemical (corrosion) reaction. Material selection is the key parameter for controlling corrosion, but we cannot neglect the importance of proper design. In many structures, a lack of design consideration the weakest link in corrosion control.

The classic book on corrosion science and engineering—now in a valuable new edition. Corrosion can be controlled in several ways: Variation of conductivity and molar conductivity with concentration.

Select and apply appropriate prevention and mitigation measures to control corrosion. Continuously monitor equipment and conditions to determine the effectiveness of control measures and make adjustments if necessary. Now you can turn to corrosion engineering for expert coverage of the theory and current.

Plastic and waxes are often sprayed onto metal surfaces. Corrosion engineering is the field dedicated to controlling and preventing corrosion. Corrosion control strategy involves two facets, namely corrosion control against production fluids and corrosion control against seawater.

The use of chemical inhibitors for corrosion control against production fluids is widespread in the oil industry. It contains general information on what corrosion is, factors to consider, common forms of corrosion and the importance of corrosion prevention. This helps prevent the onset of corrosion and even stop it from worsening.